Looking for the Right

One-stop Repair shop for your motor/generator?

Workshop

Electrical Services

Workshop

Electrical Services

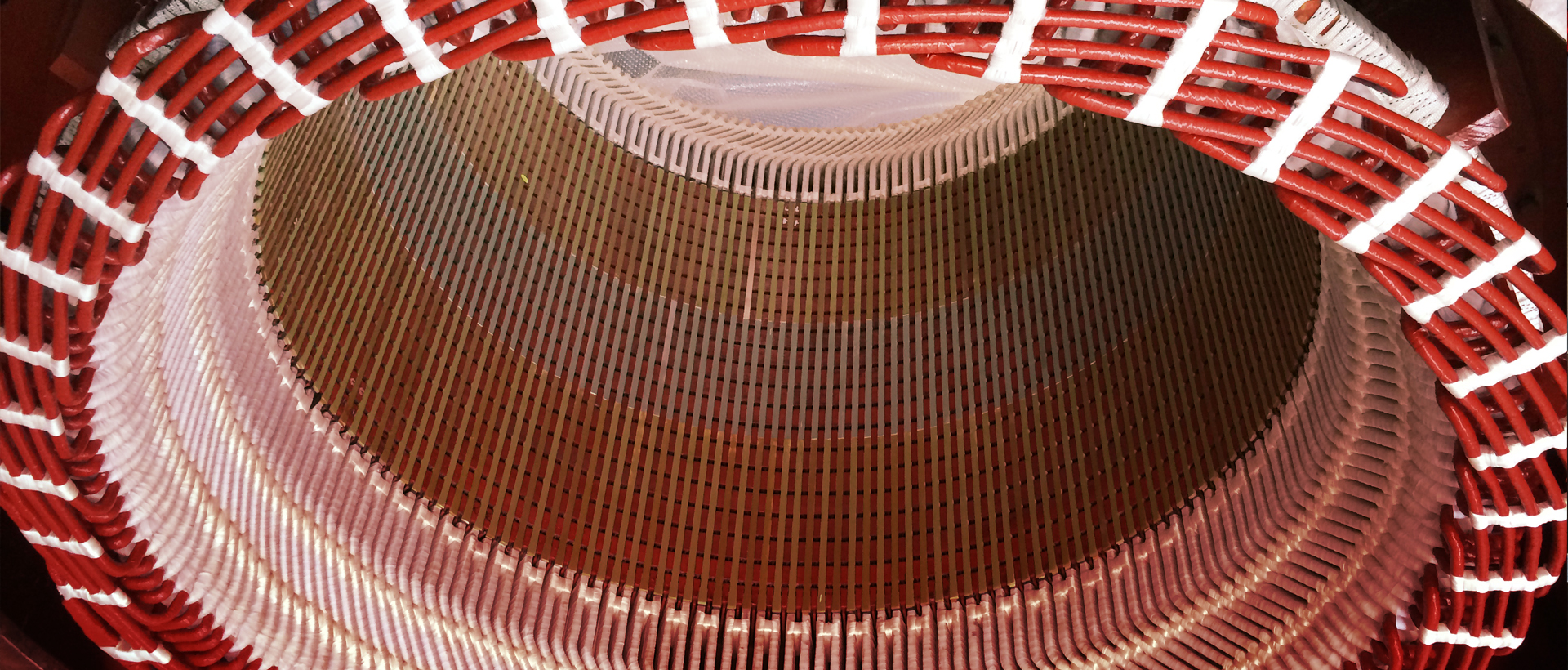

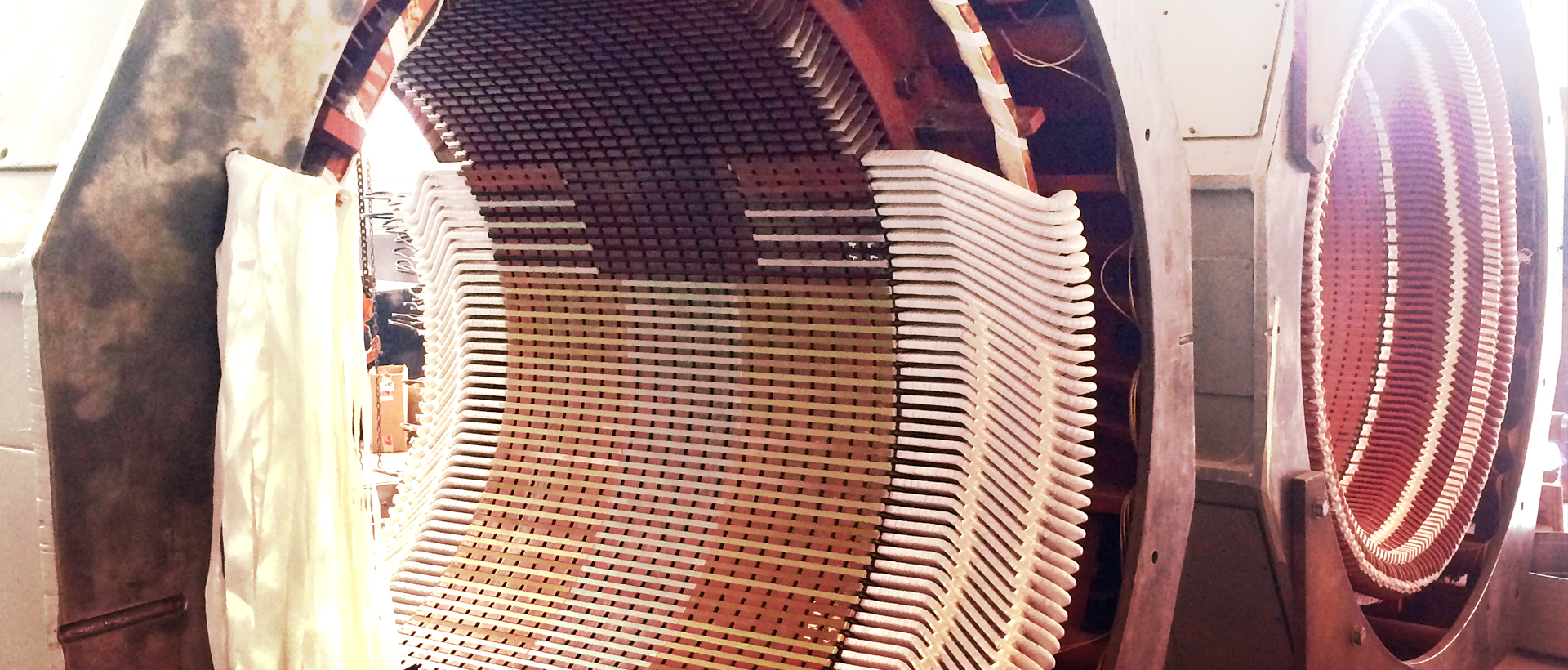

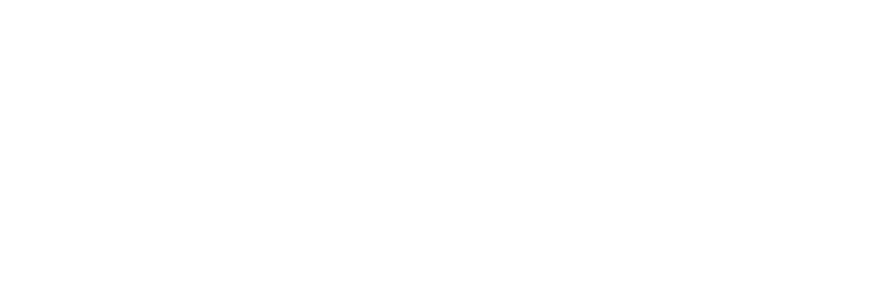

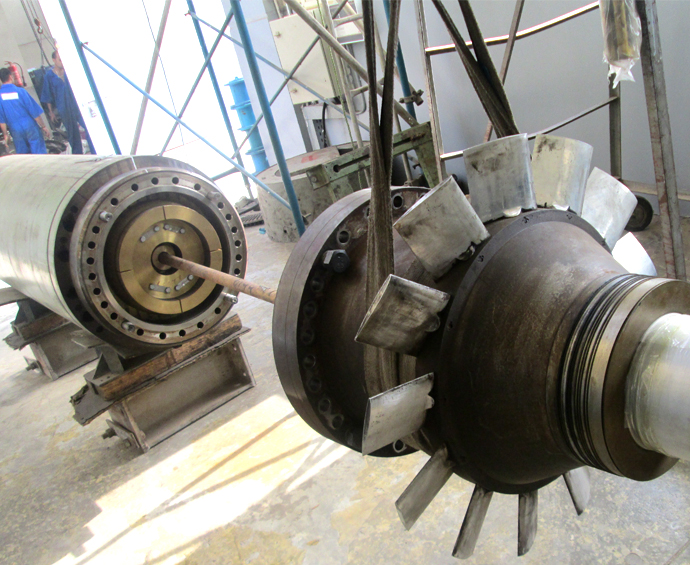

- Rewind, repair & overhaul of AC/DC low & medium voltage motors & generators.

- Frames up to 30 Tons of weight.

Workshop

Mechanical Services

Workshop

Mechanical Services

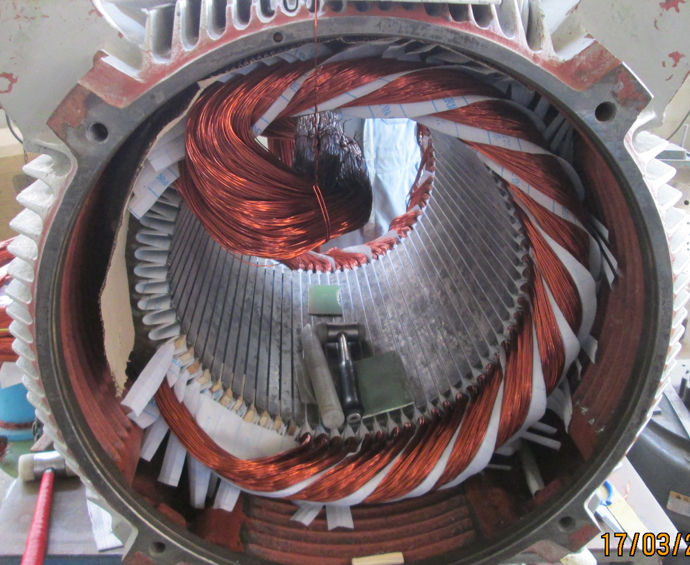

- Shaft & bearing housing repair, dynamic balancing, sleeve bearing overhaul & repair.

- Machining capacity up to 8 meters length and 3 meters diameter.

Machine Health

Condition Monitoring

Machine Health

Condition Monitoring

- Vibration Analysis

- Thermography

- Online & offline electrical measurements.

- Winding insulation condition assessment.

- Surge & tan-delta test.

Life expectancy analysis.

On-site

Services

On-site

Services

- Startup & commissioning.

- Laser alignment

- Inspection & root cause analysis.

- Sleeve bearing service

Explosion Proof

Motors

Explosion Proof

Motors

- Repair & overhaul of Ex motors to IECEX 60079 standards.

- All protection designs (d-e-n-p)

Some Statistics About Us

WORKSHOP Statistics

until Present

YEARS OF

EXPERIENCE

TECHNICIANS &

WORKERS

JOB per

YEAR

With handling capacity up to 30 tons of weight & 9 meters of height

MOTOR REPAIR TECHNICAL STATISTICS

up to

MEGA WATT

POWER

kilo amper

CURRENT

kilo VOLT

VOLTAGE

MVA

TURBO GENERATOR

ton

frame

ACCREDITATION

AUTHORIZED SERVICE PARTNERS FOR PREMIUM BRANDS

SIEMENS AG

GERMANY

MARELLI MOTORI

ITALY

ELIN MOTOREN

AUSTRIA

INDAR

SPAIN

Our Services

Below are some of

the many repair services we offer:

Within our one-stop shop, we offer the following list of electrical and mechanical repair jobs delivering the premium quality that has always been linked to our name.

Client satisfaction has always been and will remain our prime concern.

- MV rotor & stator rewind

- LV rotor & stator rewind

- Core repair & replacement

- Rotor rebarring

- DC field & armature rewind

- Slip ring repair & manufacturing

- Brush lifting device repair

- Oil transformers rewind and overhaul

- Control panels design & build

- Servo motors services

- Geared motors repair

- Electrical Diagnostics

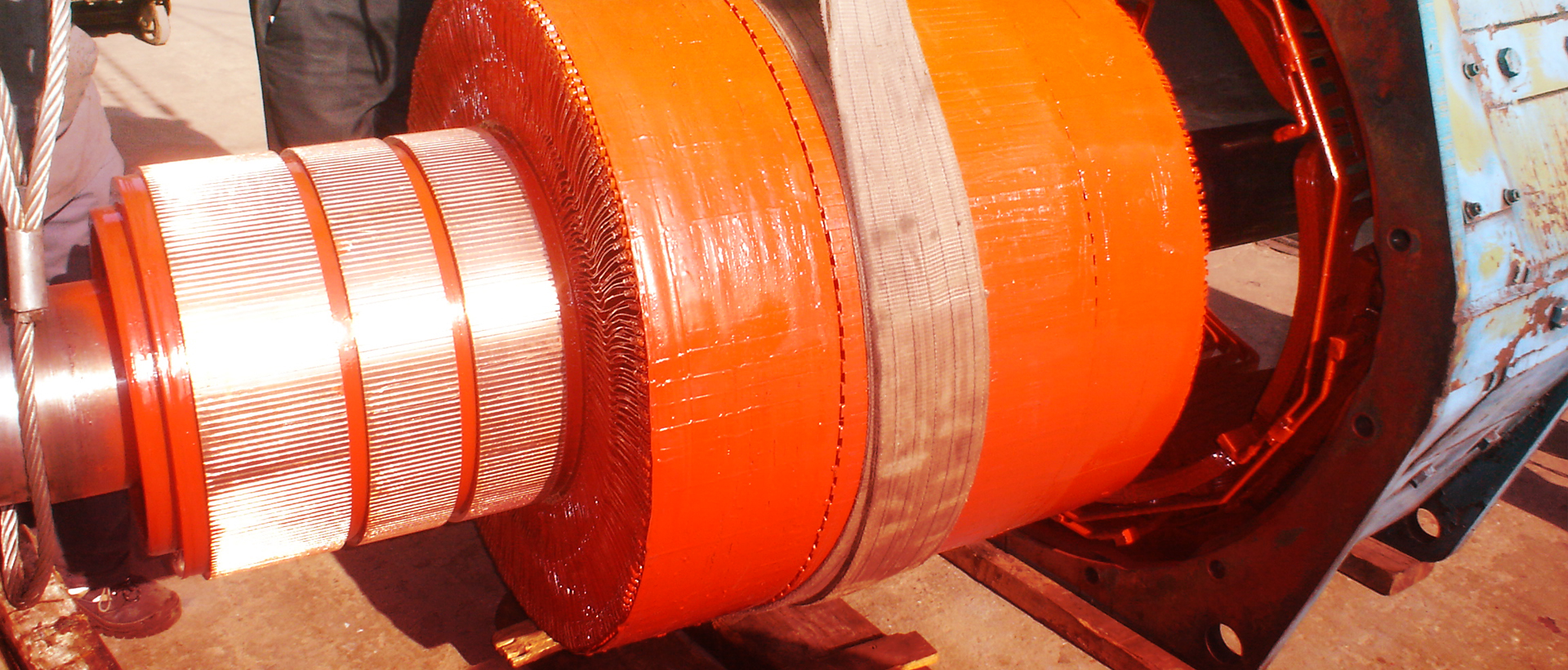

- Turbo generators overhaul

- Retaining rings inspection & replacement

- Precise dynamic balancing

- Shaft rebuilding

- Metal spray

- Hard chrome plating

- Complete shaft manufacturing

- NDT (ultra-sound, MPI, LP)

- Sleeve bearing rebabit

- Bearing housing repair

- OEM spare parts supply

- Spare parts reverse engineering & manufacturing

- Submersible pumps repair

- Lifting magnets repair

- Bailer brakes rewind

- Ex motors repair to standard/certificate

certificationS

hse & qm iso certified

for guaranteed best rewind practices

ISO 9001

TUO - GERMANY

ISO 45001

TUO - GERMANY

AEMT

MEMBER

easa

MEMBER

ouR VALUES

Why Choose BIRAF?

REPAIR TO STANDARD

We follow the best rewind procedures to maintain machine efficiency according to best code of practice.

Only high quality materials are used not only to restore but also to exceed original manufacturer specification.

Precise machining and balancing for smooth and long life time operation.

trusted & RELIABLE

Honesty and dedication to our craft is our core value and drive.

We built our name over decades of hard work delivering premium services to our clients across the region.

Join our long list of satisfied clients and leave your technical challenges within the safe hands of our skilled engineers.

TESTED & Guaranteed

We always conduct root cause analysis before repair execution to assure expected operation.

All finished parts are tested to relevant standard as a part of our QM system.

We guarantee our job with a minimum warranty period of six months that could be extended upon request.

Testimonials

What Our Clients Say

Schedule Your Appointment Today

Call: +20 238 206 829

Get in touch with our specialized team

Address:

P 108-110 street 46,

3rd Industrial Zone

6th of October City

Giza - Egypt

EMAIL:

info@biraf.com

sales@biraf.com

Working HOURS:

Monday–Saturday:

08:00–16:00